I’ve worked at Tor Books for nearly twenty years and I had never visited our bindery before. As the art director, I’ve been to our jacket printer, of course, but my job usually ends there. I had never been to the place where the guts of the books are printed, bound, and shipped. What better excuse to remedy that than to watch A Memory of Light—the final volume of a series that has been with me my entire career—go from rolls of clean white paper to shiny new hardcover books? A trip to historic Gettysburg, Pennsylvania to Quad Graphics was definitely in order.

When I arrived they were still well into a process that would take a few weeks to complete. The first batches are packed and shipped by truck to the most far-off places, working back to more local regions. I’m told it is unusual to be able to see every piece of the process on one book, but with such a massive print run, I was able to see AMoL at nearly every stage.

Here is our walk though the process….

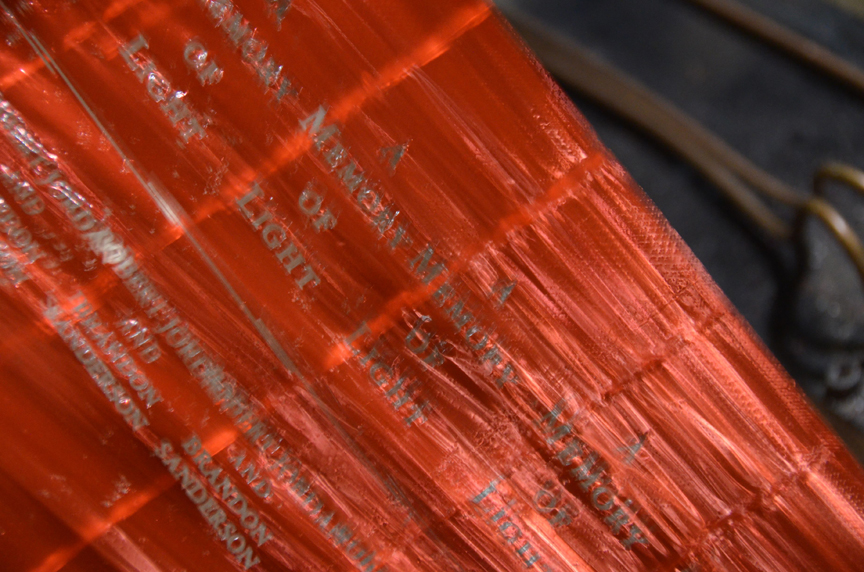

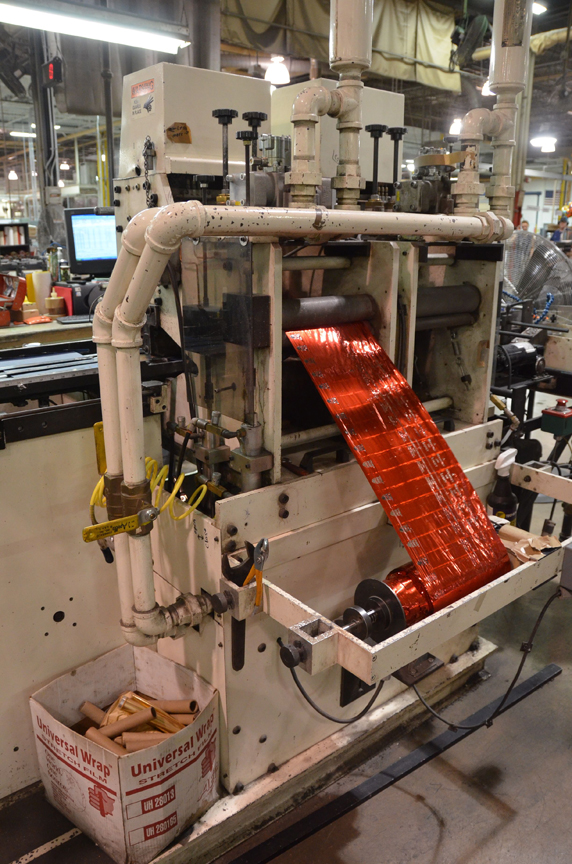

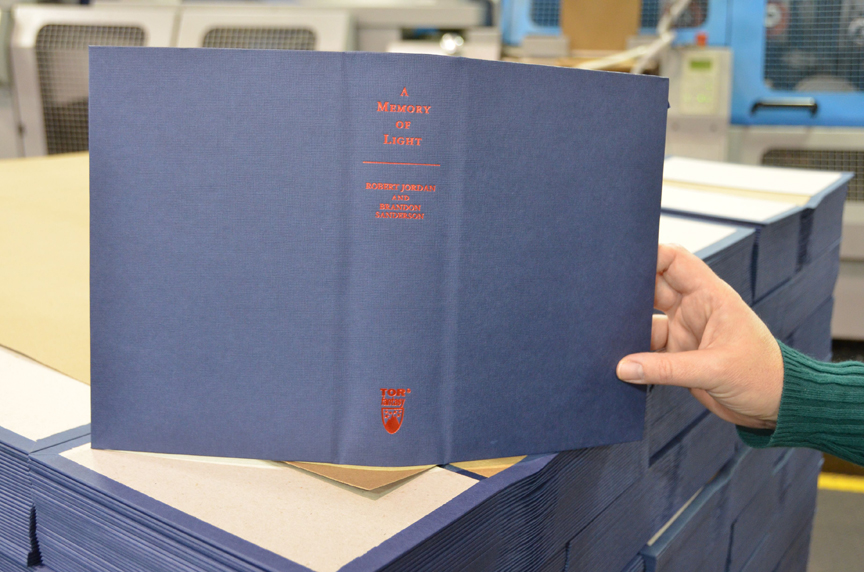

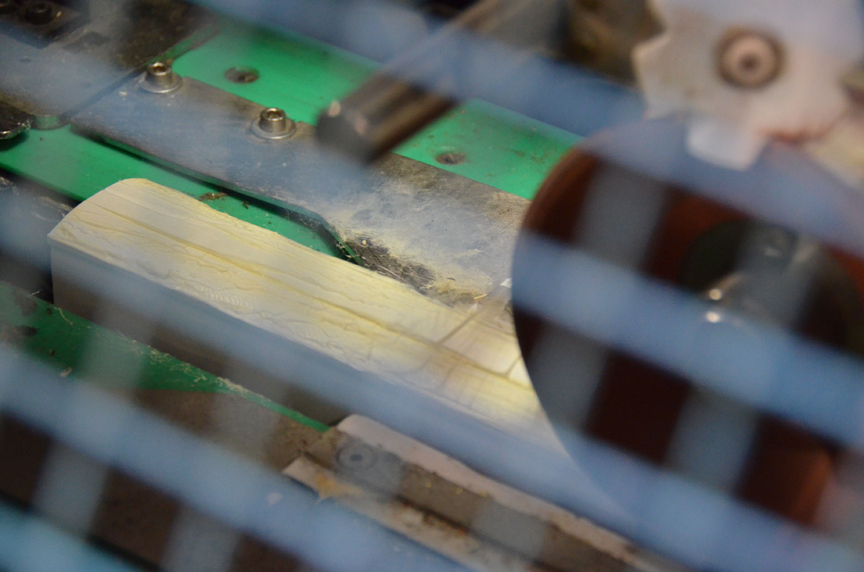

In one corner of the plant, the spines of the hardcover cases were being stamped with red foil. A quick process of heat and pressure.

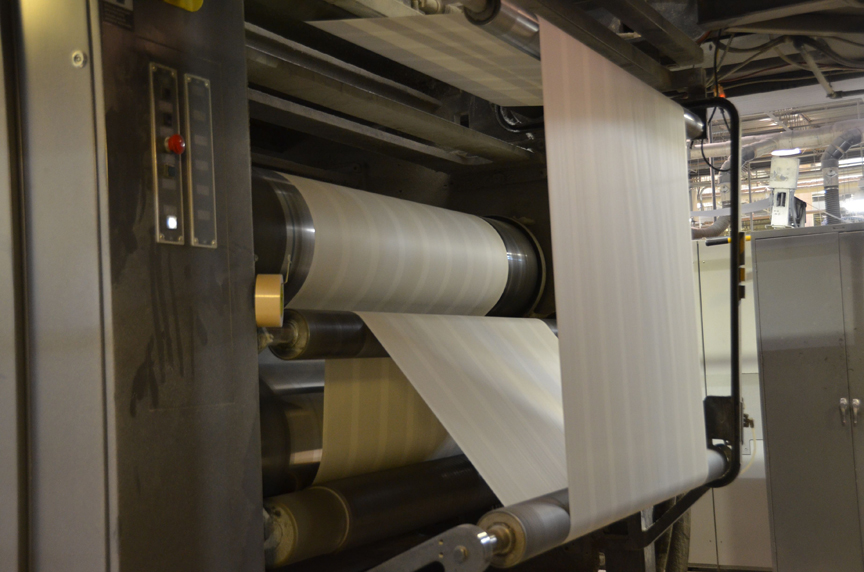

Meanwhile, the text is being prepared. It all starts with paper. Lots and lots of paper. Paper stacked and warehoused like the last scene in Raiders of the Lost Ark.

The 50” rolls are spooled into the offset printer. Here you can see one in use and another ready to engage the moment the first runs out.

That bit of blurry grey area on the paper, that’s A Memory of Light.

From one giant sheet, the printer folds and then cuts the paper into 32 page bunches called signatures. In this case, it was a chunk of the chapter titled “The Last Battle.”

Signatures on the move.

Signatures stacked.

…and ready to move into the next phase.

If you look in the middle ground of the photo below, you’ll see the skid with the signatures numbered 27 on it…

….those signatures are placed into a long machine that is a series of pockets. These pockets will drop each signature in descending order (note that this is pocket number 27) thereby stacking the pages of the book in order. (I was told The Way of Kings was so long that they ran out of pockets and had to run the book through twice.)

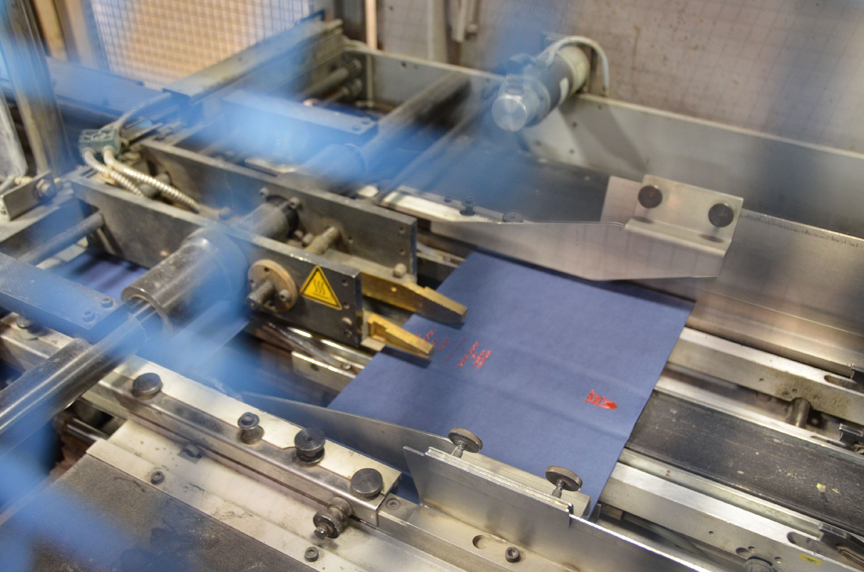

It’s a bit blurry but you can see the book zooming by below the green shelf.

The collected pages are then upturned and shaken until they line up neatly on the bottom.

Glue is laid on the spine and the endpapers attached.

At this point it’s almost like a messy paperback.

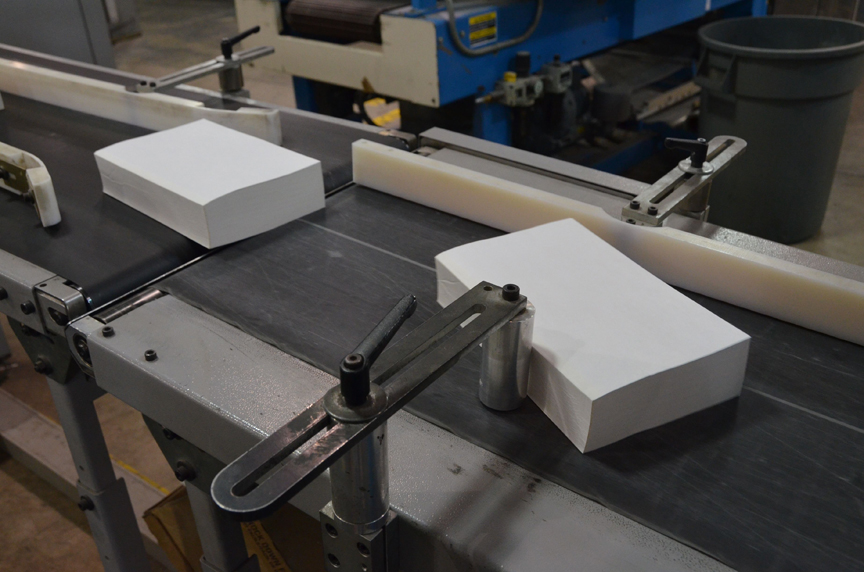

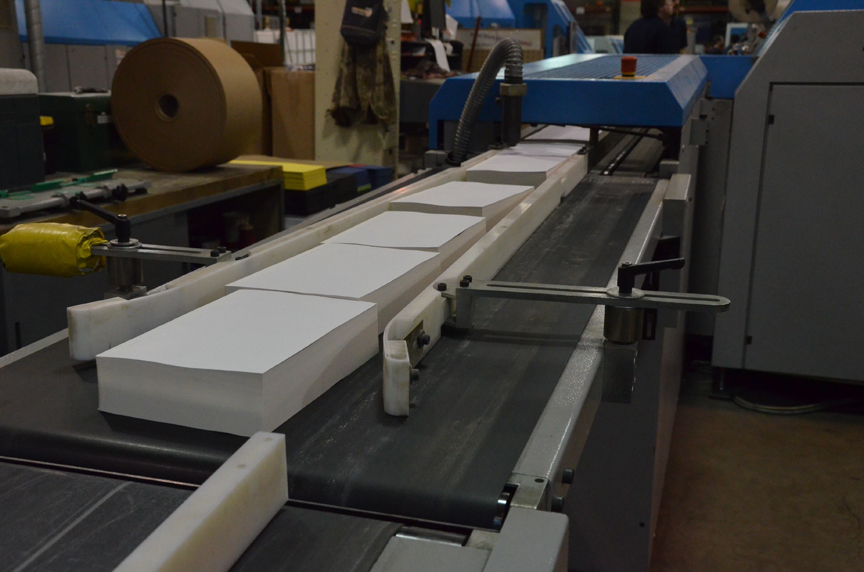

Moving on to the next station.

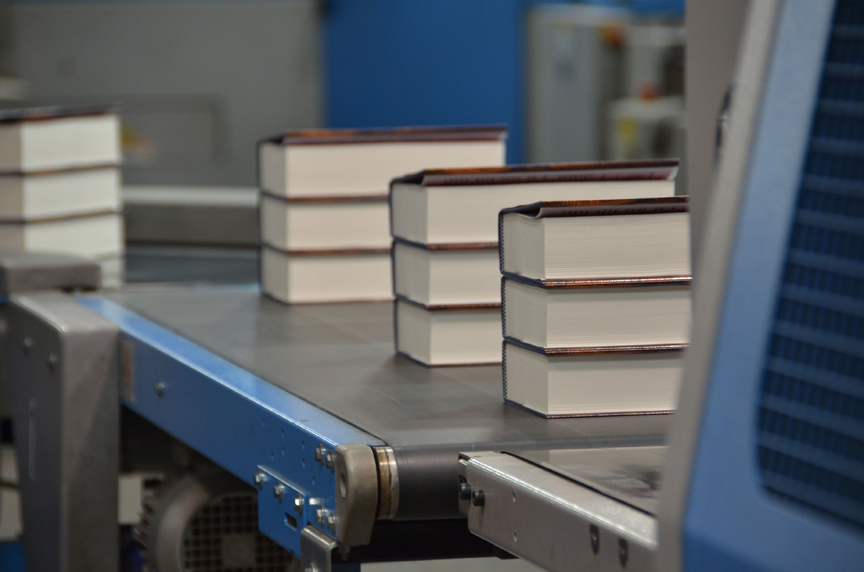

Here they are being trimmed into a neat block of text.

And on the move again.

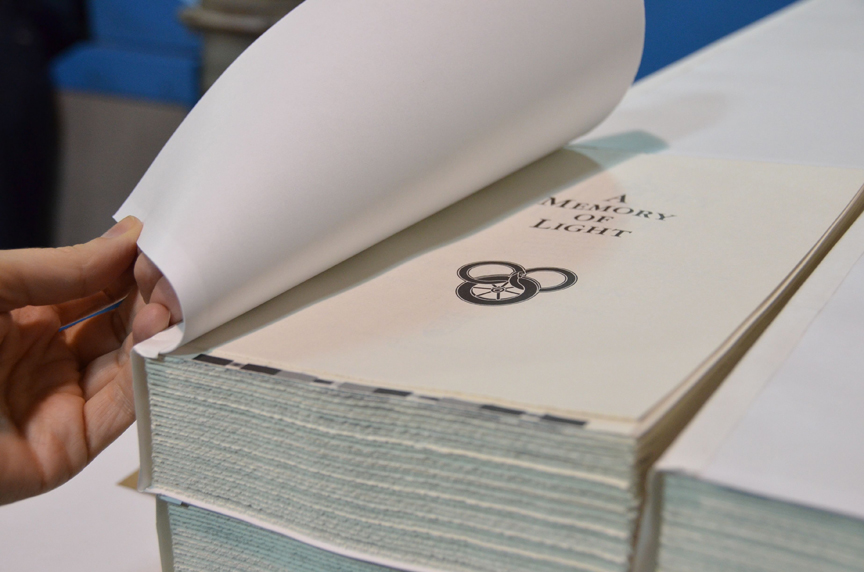

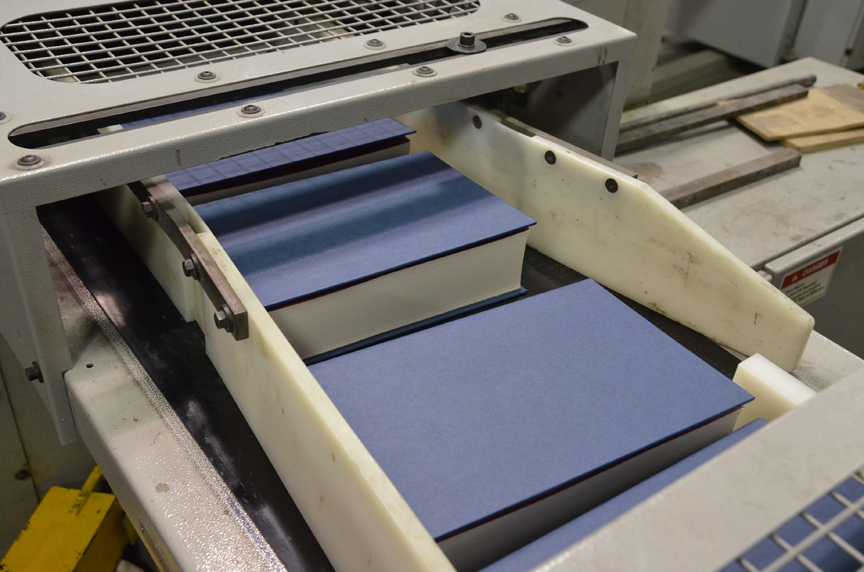

Stacks of A Memory of Light now ready to have hardcover cases attached.

The cases are stacked on top of a machine and drop down into it…

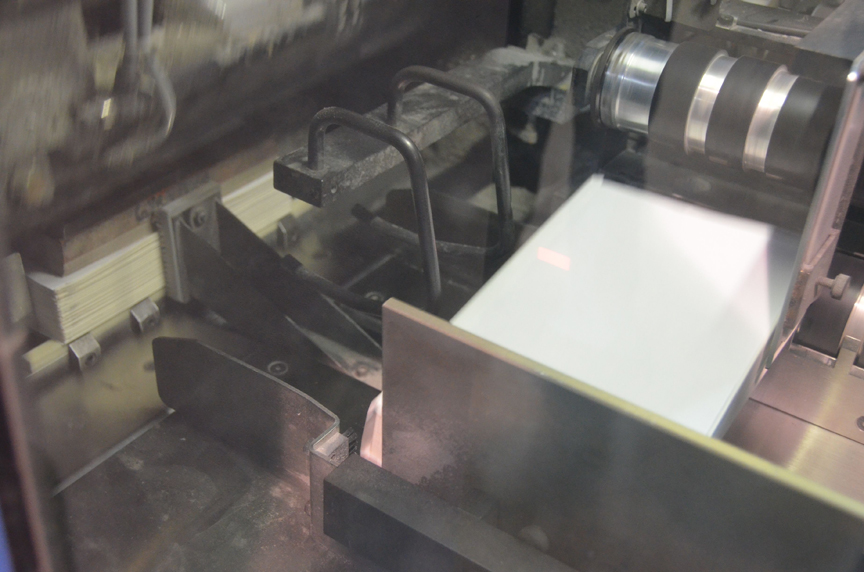

…while a dry stringy glue is laid down on the spine.

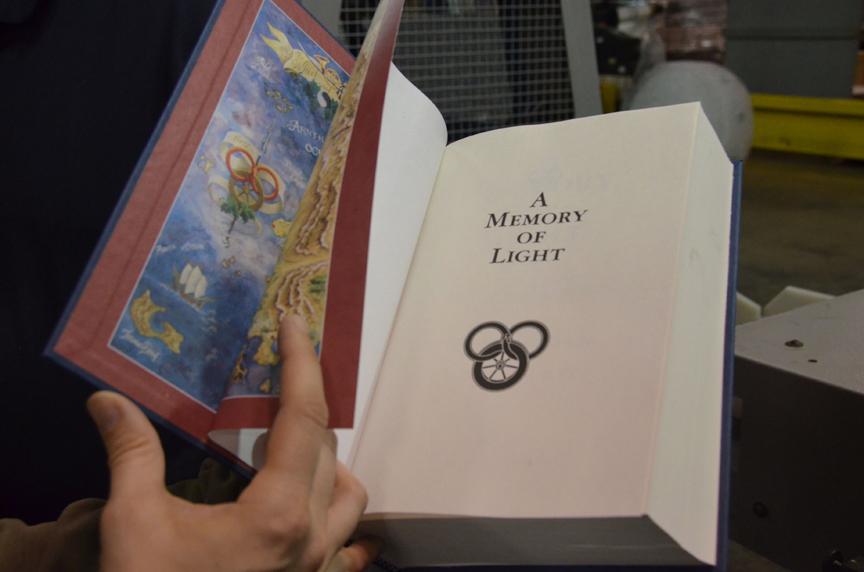

Through the machine the text block and case are connected and…

…a book! But a naked one.

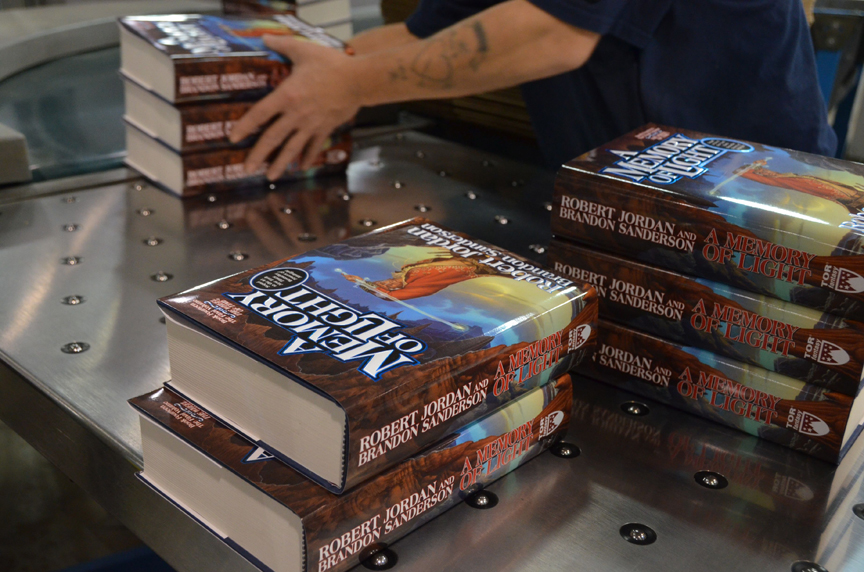

The jackets (you can see the white undersides of them below) are then fed through a machine that gathers up the pages….

…and folds the jacket around the hardcover case.

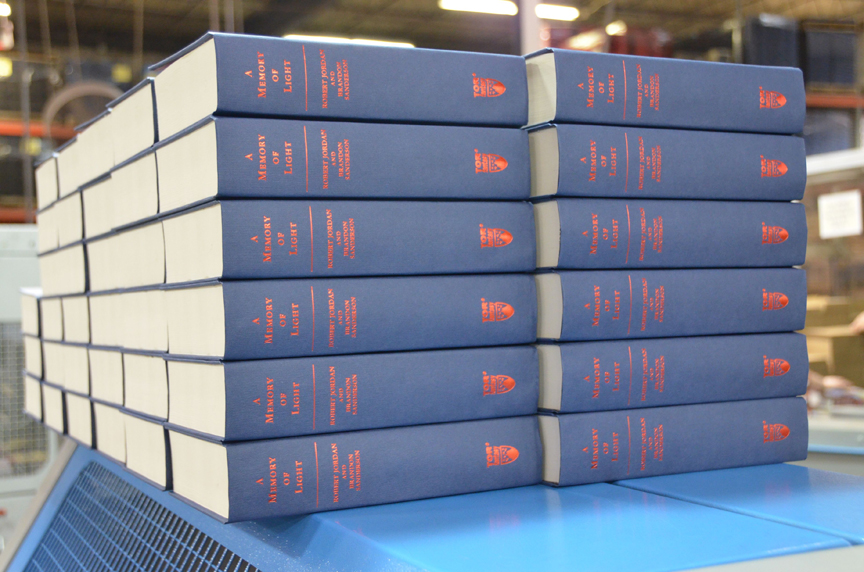

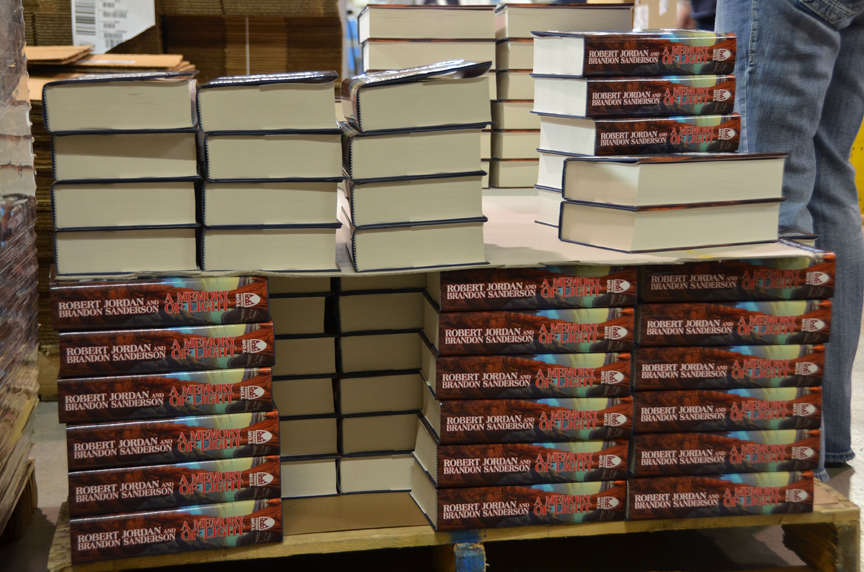

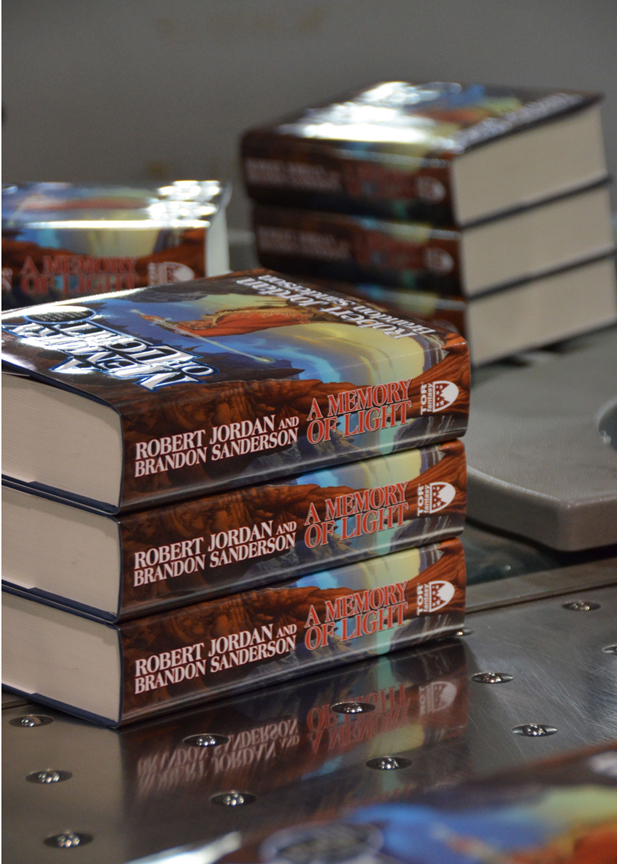

And now we have our final product.

Each one examined for quality control….

…and then placed into cartons for shipping.

The whole process looked like a marvelous bit of Suessian-magic to me, with long conveyer belts that doubled up and looped around. Everywhere we looked the warehouse was full of twelve foot stacks of the book in various stages of production. Looking at so many individual editions was a remarkable way to visualize the scope of Robert Jordan’s fan base.

I was very grateful to see this part of the process. My thanks to Jim Kapp, Tor’s production manager, for setting up the trip. And of course a huge thanks to Carter, Sally, Chris and everyone at Quad Graphics for inviting us in and letting us peek under the hood. If you have read A Memory of Light, these are the behind-the-scenes folks that have had a hand on each and every copy.

This article was originally posted on December 13, 2012

Irene Gallo is the Art Director at Tor Books.

Thanks, Irene. That was awesome!

Irene – maybe I’m losing my mind but didn’t Tor.com run this piece last year before AMOL came out?

Rob the confused….

We did. Sorry, we missed the “previously posted” line. We’ll put that in. We’ll have a few encore posts throughout the week so that our own production and editorial elves can enjoy the holiday. ;-)

Rob:While the subject of your madness cannot be resolved, yes, tor did run this article last year. I’m guessing many of the tor.com staff are flitting off in Stubby to partake of fine meals Martian turkey-beast and filleted womp-rat.

Irene – thank the Light!

SH- in Stubby, I’d assume they’d be eating ration bars and drinking Tang.

Hmm, they really should describe what the accomodations and provisioning in Stubby are like. I’m picturing stainless steel, purple velvet and the Food Network kitchens.

We actually have thought about commissioning a cross section drawing of the ole ship. Hmmm….

Thank you for sharing this peek into the very convoluted process!

A “chunk” of the chapter. Don’t know why that made me giggle.

Rancho@9 – Could it be because “The Last Battle” was almost long enough itself to be a short book? That chapter left me phyically exhausted when I got to the end of it.

One of the more fascinating posts Tor.com has published, thanks for reposting it!

I think I saw a typo in signature 27, but it was going kind of fast so I’m not sure.

I’m curious. How long does the process take, start to finish, to produce a book with its jacket on?

@13

It depends on the run size. You can’t begin the binding process until you have some of every signature. So assuming the all signatures are available, and everything configured and ready to go on the Binding line, you can produce about 3000 good books per hour.

So the time per book is small and it is the setup and makeready that is really time consuming. Since the cost to makeready for a 10,000 count order and a 100,000 count order are the same, publishers like Tor like to produce books for authors who are going to sell lots and lots of books. Thus amortizing the setup costs over more units and keeping their per unit cost and low as possible.

I’ve noticed that some books seem to skip the “trimming” part. Why is that? I first remember seeing it on A Series of Unfortunate Events.

@15 Shay,

In the old days, that was a “deckle edge.” It was the thin feathery edge created when people made single sheets of paper.

Nowadays publishers sometimes ask for a “rough front,” which is a cheaper way to get that “ye olde story book” feel with mass produced rolls of paper.

I was just wondering, do you know how much it costs to print a book? I mean, what are the costs associated with a book- to print, ship, market…

Thanks :D

There is a typo in the word “decsending”; it should look like the shoulders-and-downwards of “condescending”.